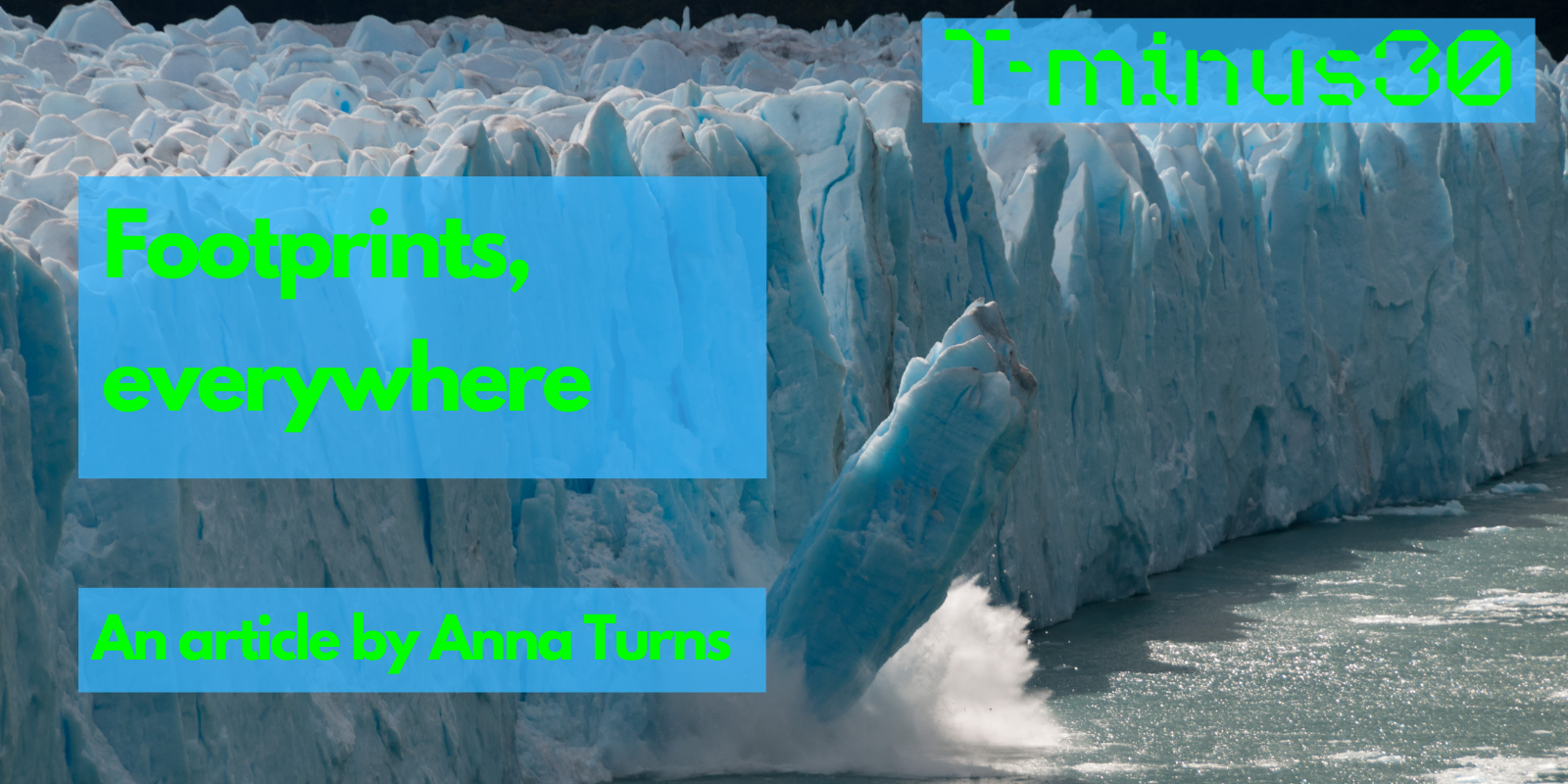

Footprints, everywhere

Global supply chains need a rethink because we can only truly reduce our environmental footprint once we have measured the impacts of everything we buy and use, says Anna Turns

Both the coronavirus pandemic and Brexit are stark reminders of how reliant we are on complex global supply chains for pretty much everything. When the finely-tuned balance of supply and demand is put under enormous strain, something has to give. Last spring, our shopping habits changed rapidly as online deliveries soared, and farmers, chefs, even event organisers pivoted to supply goods direct to consumers in their homes. But many businesses folded.

While it was arguably more difficult for big multinationals to shift their trajectory, like that of a container ship wedged across the Suez canal, many smaller businesses acted like nimble dinghy boats, quickly changing direction and pivoting to adapt to shifting markets.

The sudden rush to buy toilet rolls, pasta, and even hot tubs was perhaps a reminder that none of this is magic. Everything is produced somewhere from raw materials and most then gets transported across oceans by planes or ships before being dispatched to the supermarket shelves or online shopping warehouses.

So whenever we buy food, toys for our children, a new outfit or mobile phone, or place an order for stock that gets made thousands of miles away, it’s important to remember that it all has an environmental impact. The cotton used to make your T-shirt consumes vast amounts of water, pesticides, and fertiliser. The many metals in your mobile phone have been mined in places like Chile, Australia, South Africa before being transformed in a factory in Asia and then shipped on. The toxic chemicals used to tan the leather used to make sofas and handbags might be leaching into Indian waterways. All of these production processes, from the harvesting to the distribution, involve the emission of greenhouse gases that directly contribute to the climate crisis too.

Today’s economic system is based on a linear model of make, take and dispose. It’s wasteful of resources and energy and it’s far from future-proof. On a planet with seven billion people, and more than nine billion by 2050, frankly, it’s irresponsible and greedy. The carbon impacts of a supply chain might well be felt most in the Global South whilst the products resulting from that process benefit people in the Global North.

So a radical shift to a more equitable framework is essential. More companies, and forward-thinking cities like Amsterdam, are now working towards creating a more sustainable model. A circular economy involves designing more streamlined, energy efficient systems and products that can be reused, repaired, and recycled with minimum waste because there is no away.

We also need to take a more global view of the environmental impact something might have. That goes beyond choosing an item becomes it claims to be plastic-free or comes in biodegradable packaging. By demanding better transparency, we can find out more about how the food we eat was produced and transported or whether the clothes we wear were manufactured without huge chemical inputs into the waterways.

At the moment, one of the best ways of ensuring best practice in terms of ethics and environmental standards is to look for brands that have met the criteria for certain certification such as organic, B Corps, or Fairtrade. But no certification system is fool proof and in the future, supply chains might well rely more heavily on blockchain. Some high-end niche products like spirits, tuna steaks and even silver jewellery are adopting this clever tech to allow the consumer, and all parties involved in the process, to scan a barcode and find out all sorts of information – where and when a fish was caught, whether a metal was mined responsibly or the name of the farmer who grew the barley used to distil a bottle of whisky.

Roasting giant Nestle recently announced it would be investing $790million in supply chain transparency for its coffee, hoping to use blockchain to trace all supplies back to groups of farmers by 2025. Once the true impacts of a supply chain have been calculated and quantified, it’s much easier to set achievable targets and clock improvements as we speed towards the need to reach net zero greenhouse gas emissions by 2050, if not before. Blockchain alone is not the quick-fix solution; it’s not cheap and although it guarantees traceability, it doesn’t promise sustainability.

Another grey area remains. Often total carbon emissions are measured by nation and might include internal air travel but not international flights or shipping costs because they go beyond geopolitical boundaries. Those dots all need to be joined up and that’s something a new institute in Japan aims to do.

Ocean health, biodiversity, clean air, and the Amazon rainforest are all by their very nature, harder to regulate, but everyone would benefit from better stewardship of these ‘global commons’. The University of Tokyo’s new Center for Global Commons (CGC) is developing new ways to enable international collaboration. Their new Global Commons Stewardship Index ranks countries, not just on their domestic impacts but on imports and exports too so it takes into account this ‘spillover effect’ and highlights that we have responsibility beyond our borders.

Ultimately, as leaders in government, business, local communities and households, we all have agency to hold power to account. By voting with our pounds or dollars or euros, we can support brands and invest in systems that are contributing to a more circular economy, reducing carbon emissions, protecting our global commons and being as transparent about every link in their supply chain as possible. Only then can we tread more lightly and genuinely reduce our environmental footprint.

Each of us has an environmental footprint – you can calculate yours here: footprint.wwf.org.uk

By Anna Turns